The standard CO2 cleaning setup consists of:

- CO2 cylinder

- Fittings & PTFE lined hose

- Gun mechanism

- Venturinozzle

- Extras include pressure gauge, filter (recommended)

Orders & Support: +44 (0) 1543 500 044

Orders & Support: +44 (0) 1543 500 044

Carbon Dioxide (CO2) Snow Cleaning systems are for the most part straightforward, they consist of a CO2 source, cylinder fitting, a nozzle with an internal orifice, an on/off valve, and the means to transport the CO2 from the source to the nozzle. The products are made with a PTFE lined flexible stainless steel hosing and available on/off controls include solenoid, pneumatic, or manual valves, or hand guns. These products are designed for precision cleaning.

The standard unit is supplied with two nozzles - one asymmetric venturi stainless steel on the unit and a second low velocity nozzle, an on/off gun, a 10 foot flexible PTFE lined stainless steel hose, and a cylinder fitting. Optional submicron sintered stainless steel filter,s and an 0 - 2000 psi pressure gauge can be added.

CO2 cylinder fittings are available for British (BS-8), North American (CGA320 or CGA716), Europe (DIN-6) and Japan (JIS22R) style cylinders. The DIN-6 is the ISO international standard and works in many other countries. If these fittings don't match your requirments, please contact us to discuss further.

The standard CO2 cleaning setup consists of:

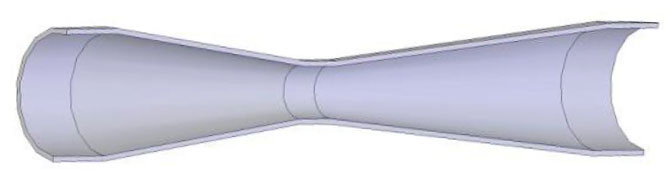

Nozzle design is the most important factor for effective CO2 snow cleaning, with the Venturi orifice angle and length determine velocity of gas and size of CO2 snow. Constant enthalpy expansion within the nozzle ensures snow stream is kept as uniform as possible for reliable, repeatable cleaning.

Cryogenic Exposure is a risk. The stream is cold, -80C. Exposure of the stream to your skin will freeze it, though not instantaneously. We have tested short exposures here and found no problems. Running the stream over your fingers poses no safety issues (we tested this on ourselves); while holding the stream on yourself at one spot will cause a problem after a few seconds. Exposure is similar to liquid nitrogen. The user will be instantly aware of exposure and will withdraw hand. Never aim the stream at another person. Please wear safety glasses when using this equipment. And follow all safety rules for using compressed gases. See your safety officer or call if you have questions.

Carbon Dioxide Exposure and Oxygen Depletion - If too much carbon dioxide enters your work area, your available oxygen decreases. But far more serious, is excessive carbon dioxide exposure. If you recall the movie Apollo 13, the CO2 buildup was a greater risk than the oxygen consumption. The same applies here. Workplace exposure should be maintained below 0.1% for the entire workday and short term exposures limited to 0.5% for short term exposures. The air we breathe normally contains about 0.04 percent carbon dioxide. Building codes may require sensors and air exchanges if the room carbon dioxide level exceeds 1000 ppm.