Optix

Optix

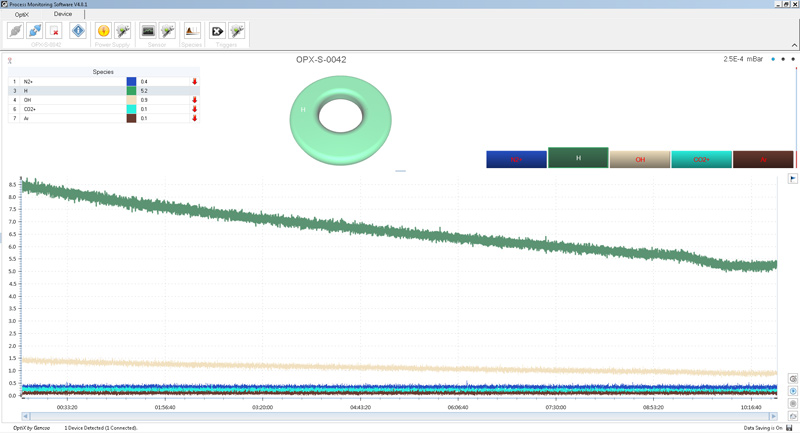

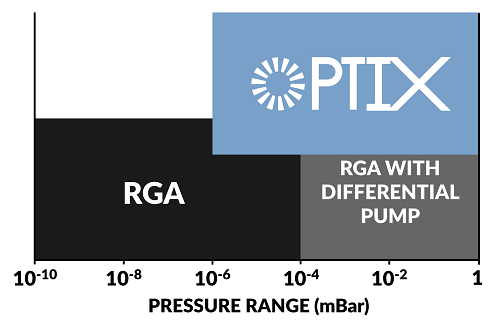

Optix is a multi-purpose instrument for rapid gas sensing in any vacuum environment, functioning through a wide range of operating pressures to cater for most industrial vacuum production processes without any requirement for a differential pumping system unless atmospheric sampling.

Separated from chemicals by an optical window, Optix uses a remote plasma spectroscopy concept which generates a small plasma within the sensor head. A built-in spectrometer analyzes the plasma, automatically interpreting the light spectrum to provide qualitative measurement of the presence and concentration of gas within the vacuum.

The Optix spectral information and sophisticated back-end software creates a range of uses for a wide range of applications, including contaminating processes involving hydrocarbons, solvents and long-chain polymers.

Small changes are made to the device in the case of sensing CVD and ALD type processes in order to prevent contamination of the plasma head. Sensing from atmosphere is also possible with a small roughing pump to bring the gases into the sensor.

Optix is very portable and easily switched between different vacuum systems or hand-carried in a small box to customer sites. It also offers an ultra-high sensitivity single gas option for dedicated leak detection.

Enquire about this Product